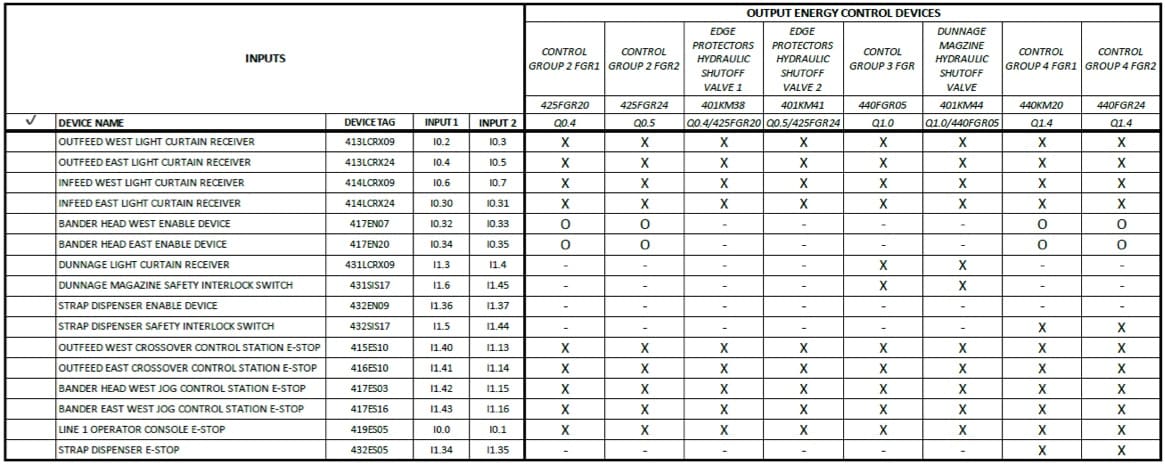

Part of this analysis results in a validation checklist which identifies the expected reaction of the safety related part of the control system (SRP/CS) under demand conditions (i.e. Safe state of actuators based on input element conditions). Additionally, faults are injected into the SRP/CS to ensure the fail-safe nature of the design has been achieved in the installation. This documentation and procedure then become part of the user's periodic maintenance of the safety system.